Polyurethane – Quality and Selection

Polyurethane – Quality and Selection

Alchemy-Spetec offers one of the most technologically advanced grout product lines currently on the market, including our unique, highly-effective Spetec PUR HighFoamer. Known in the industry for its expansive properties, this product is the only one in its class that can shut down gushing leaks and fill voids as quickly and effectively as it does. We offer a wide variety of materials, including slab lifting foams, deep-soil lifting foams, soil stabilization foams, injection resins for crack leak seal, foams for curtain grouting leak seal, acrylic injection resins that penetrate thin cracks and saturate soil, epoxy resins for structural repair and preventative waterstop products. The superior quality of these materials guarantees fewer callbacks from your customers. Many of these products are also certified for contact with potable water, making them safer for the environment.

Equipment and Accessories Selection

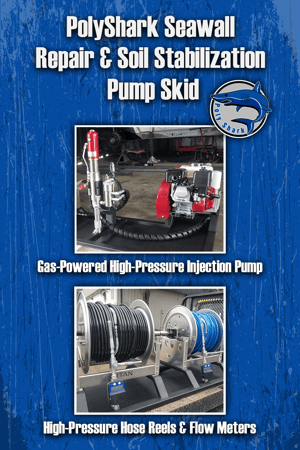

We’re a one-stop shop for all things polyurethane concrete repair, with one of the most versatile equipment and accessory product lines in the industry. Once you’ve picked out the product that best fits your needs, we can provide it all: pumps, hoses, packers/ports, and specialty accessories.

Tech Support – Experience and Dedication

Do you need technical support? You’re in luck—we’re home to the industry’s premier technical support squad. Averaging decades of experience, we also pride ourselves in being incredibly responsive. For example, our team was recently called on to assist with a large metro project in the Western United States. The customer informed us at 4pm on Monday evening that assistance was needed at 9am the very next day! Our Technical Services Director Charlie Lerman, Vice President Jim Spiegel, and Western Regional Sales Manager (that's me!) traveled to the site Monday evening to help diagnose the location of the leaks and develop an action plan. Our Technical Services Manager Charlie remained on site for two more days to ensure that the project was successful. Depending on the size and scope of the project, response time and participating team members may vary, but this story serves to illustrate the lengths we will go to assist customers.

Training and Education

We offer the industry's most thorough training and education for both Leak Seal and Geotech polyurethane infrastructure repair. We conduct training workshops at distributor locations, consult with contractors on job sites, and hold intensive programs twice a year at our headquarters in Tucker, GA. We also offer in-depth online training videos to current customers.

Marketing Support

Our Marketing Department provides qualified customers with product application illustrations and photos for use on websites, customized brochure PDFs for printing, and truck signage graphics. We also offer the use of our educational videos and animations. Lastly, we’re available for guidance on everything from online lead capture strategies to internet advertising, and more.

We’re Committed to Your Success

The overriding theme here is our commitment to your success. Obviously, this is not totally altruistic in nature. The more successful you are, the more materials and equipment you buy. But it is 100% genuine. Our entire team understands the relationship between YOUR success and OUR success. This point of view is thoroughly ingrained in our company culture.

Want more information on Alchemy-Spetec products?

On this episode of The Injection Connection, Charlie Lerman takes over the hosting duties, welcoming Alchemy-Spetec independent rep John Ziebell. Formerly the Vice President of Operations for Deneef Construction Chemicals, Inc., John has 36 years of experience in the chemical grout industry and is currently a member of the International Concrete Repair Institute (ICRI).

On this episode of The Injection Connection, Charlie Lerman takes over the hosting duties, welcoming Alchemy-Spetec independent rep John Ziebell. Formerly the Vice President of Operations for Deneef Construction Chemicals, Inc., John has 36 years of experience in the chemical grout industry and is currently a member of the International Concrete Repair Institute (ICRI).

Single-Component Geotech Pump Skid

Single-Component Geotech Pump Skid

We understand that chemical grouting is often not the primary focus of a construction or repair job, but a water leak can often bring the rest of the job to a screeching halt until it is sealed. Job costs then start to pile up, production or facility services stay shut down as time drags on, sometimes tempers begin to flare. Sound familiar?

We understand that chemical grouting is often not the primary focus of a construction or repair job, but a water leak can often bring the rest of the job to a screeching halt until it is sealed. Job costs then start to pile up, production or facility services stay shut down as time drags on, sometimes tempers begin to flare. Sound familiar?

With 1,350 miles of coastline, Florida is home to countless seawalls. If you're a property owner or manager in the Sunshine State, you have landed in the right place. Alchemy-Spetec provides

With 1,350 miles of coastline, Florida is home to countless seawalls. If you're a property owner or manager in the Sunshine State, you have landed in the right place. Alchemy-Spetec provides

Storms, tidal action, and soil erosion constantly cause damage to seawalls. It is essential to identify any problems as early as possible. Here are the most common warning signs of seawall failure:

Storms, tidal action, and soil erosion constantly cause damage to seawalls. It is essential to identify any problems as early as possible. Here are the most common warning signs of seawall failure:

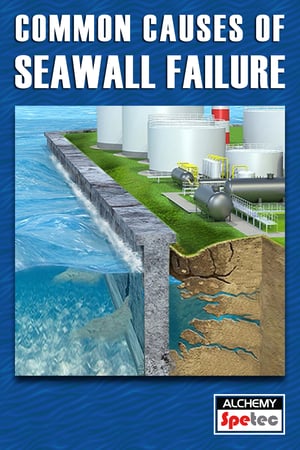

Seawalls are built to create a strong and stable barrier between a body of water and adjacent land, but why do they fail over time? Here are three common factors that can damage a seawall.

Seawalls are built to create a strong and stable barrier between a body of water and adjacent land, but why do they fail over time? Here are three common factors that can damage a seawall.

Alchemy-Spetec is pleased welcome Colt Hullander! Colt will join us as the new Director of Technical Services – Geotech Division, supporting Alchemy-Spetec customers on a wide variety of polyurethane jobs, from slab lifting to soil stabilization and seawall repair. He brings a decade of geotech experience to the team.

Alchemy-Spetec is pleased welcome Colt Hullander! Colt will join us as the new Director of Technical Services – Geotech Division, supporting Alchemy-Spetec customers on a wide variety of polyurethane jobs, from slab lifting to soil stabilization and seawall repair. He brings a decade of geotech experience to the team.

Chemical grouts have an amazingly diverse range of properties. This makes them incredibly useful for all types of waterproofing, soil modification, and structural repairs. This wide range of characteristics means that there is no one size fits all grout out there. But I get ahead of myself. Before one can select a chemical grout for a repair it is necessary to understand not only the asset to be repaired but also how and why it is failing and/or leaking. There are numerous methodologies that can be utilized to determine what is going on, but before one can start the troubleshooting one needs to understand the structure's design.

Chemical grouts have an amazingly diverse range of properties. This makes them incredibly useful for all types of waterproofing, soil modification, and structural repairs. This wide range of characteristics means that there is no one size fits all grout out there. But I get ahead of myself. Before one can select a chemical grout for a repair it is necessary to understand not only the asset to be repaired but also how and why it is failing and/or leaking. There are numerous methodologies that can be utilized to determine what is going on, but before one can start the troubleshooting one needs to understand the structure's design.

Polyurethane – Quality and Selection

Polyurethane – Quality and Selection