It’s crucial to determine if your project requires products that meet NSF/ANSI 61-5 standards for contact with drinking water. But what exactly are NSF/ANSI/CAN 61 standards? Our goal here is to provide a concise and comprehensive overview of why NSF approval is important for polyurethane geotech and leak seal materials.

It’s crucial to determine if your project requires products that meet NSF/ANSI 61-5 standards for contact with drinking water. But what exactly are NSF/ANSI/CAN 61 standards? Our goal here is to provide a concise and comprehensive overview of why NSF approval is important for polyurethane geotech and leak seal materials.

What is the NSF (National Sanitation Foundation)?

The National Sanitation Foundation develops public health standards and certification programs that help protect the world’s food, water, consumer products, and environment. Their organization ensures that adequate testing is conducted for all products that will be used in or around drinking water from source to tap.

An NSF compliance brief reads: “NSF, an independent, private, not-for-profit, third-party certification organization founded in 1944, has developed numerous health-based certification programs and consensus standards including those that relate to drinking water…The purpose of its certification program is to promote public health and enrich the quality of life. Through its Council of Public Health and Health Advisory Board, which includes EPA health professionals, it obtains guidance in developing and maintaining programs and standards. NSF also partners with code councils to ensure ongoing compliance.”

Each product must undergo rigorous testing to receive NSF approval. The manufacturer's plant and quality assurance practices must pass a thorough inspection. Voluntarily undergoing such a rigorous certification process is invaluable to all parties involved.

The SDWA (Safe Water Drinking Act)

The Safe Water Drinking Act (SDWA) gives the EPA latitude to impose criminal and civil penalties on industries that are not in compliance. In 2014 enforcement efforts policing clean water netted $163 million in penalties and fines, 155 combined years of incarceration for sentenced defendants, and $16 million in court-ordered project clean-ups.

Because so many of those defined contaminants are pertinent to even the most basic construction projects – turbidity from soil runoff, leaching from PVC pipes, potentially harmful and corrosive chemicals, and more – understanding and adhering to the law is particularly important for industry stakeholders. Contractors and engineers must be able to confidently choose vendors whose products and services won’t become the source or cause of drinking water contamination either in the short or long term. Having products that may come into contact with drinking water certified to NSF/ANSI/CAN 61 (approved for contact with drinking water), ensures compliance with the SDWA.

Alchatek NSF Approved Products and Solutions

Alchatek's NSF-certified materials are evaluated and lab-tested, and the production facilities are inspected and annually audited for re-testing to maintain certification.

The following products have received the official NSF seal of approval for contact with drinking water:

- AP Lift 430

- AP Lift 475

- AP Soil 600

- AP Fill 700

- AP Fill 720

- Spetec PUR F400

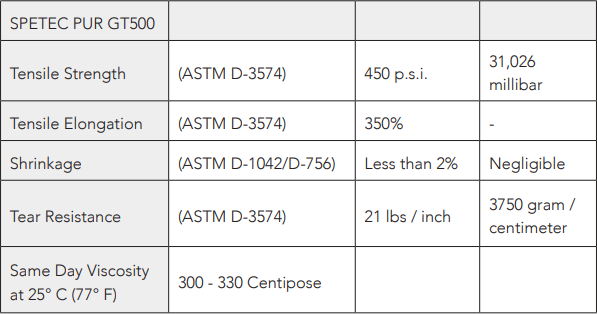

- Spetec PUR GT500

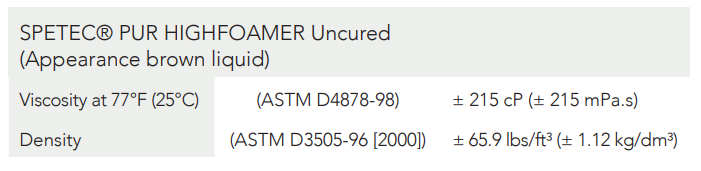

- Spetec PUR HighFoamer

- Spetec PUR H100

- Spetec PUR H200

- Spetec AG200

Alchatek's

Alchatek's

We recently

We recently

In the current rapidly evolving industry of infrastructure repair, obtaining every possible advantage is crucial. Alchemy-Spetec considers the success of your business to be our highest priority. You will gain a significant competitive advantage over your rivals with our extensive range of high-quality materials, cutting-edge equipment, industry-leading technical support, and comprehensive marketing assistance. Our organizational values are centered on securing your success in this industry.

In the current rapidly evolving industry of infrastructure repair, obtaining every possible advantage is crucial. Alchemy-Spetec considers the success of your business to be our highest priority. You will gain a significant competitive advantage over your rivals with our extensive range of high-quality materials, cutting-edge equipment, industry-leading technical support, and comprehensive marketing assistance. Our organizational values are centered on securing your success in this industry.

A major culvert restoration project was recently completed by

A major culvert restoration project was recently completed by

Join an Alchemy-Spetec Specialist to Present to Local Organizations

Join an Alchemy-Spetec Specialist to Present to Local Organizations

Using social media to market yourself and your contracting firm is essential as the world becomes more connected. Consider a LinkedIn profile to be your very own personal branding page. LinkedIn can play a significant role in your strategy for locating new clients and contacts in your field. Your name, photo, and headline are frequently the first things visitors see before even clicking on your profile. A professional headshot photo is essential for your profile page.

Using social media to market yourself and your contracting firm is essential as the world becomes more connected. Consider a LinkedIn profile to be your very own personal branding page. LinkedIn can play a significant role in your strategy for locating new clients and contacts in your field. Your name, photo, and headline are frequently the first things visitors see before even clicking on your profile. A professional headshot photo is essential for your profile page.

Back in the 1990s, the Seaholm Power Plan in the City of Austin, TX closed after four decades of operation. Recently, the entire area has been converted into an indoor-outdoor park and public space called the Seaholm Waterfront. All that's left standing of the original power plant is an intake building that the city decided to repurpose for public use as part of the project. Thirty feet below grade, are chambers that were originally designed to hold water from the river and pump it into the power plant to cool the machinery. The intake building renovation project hit a snag when they discovered that several thousand gallons of water were pouring into the chambers on a daily basis.

Back in the 1990s, the Seaholm Power Plan in the City of Austin, TX closed after four decades of operation. Recently, the entire area has been converted into an indoor-outdoor park and public space called the Seaholm Waterfront. All that's left standing of the original power plant is an intake building that the city decided to repurpose for public use as part of the project. Thirty feet below grade, are chambers that were originally designed to hold water from the river and pump it into the power plant to cool the machinery. The intake building renovation project hit a snag when they discovered that several thousand gallons of water were pouring into the chambers on a daily basis.

The Crack Injection Process

The Crack Injection Process