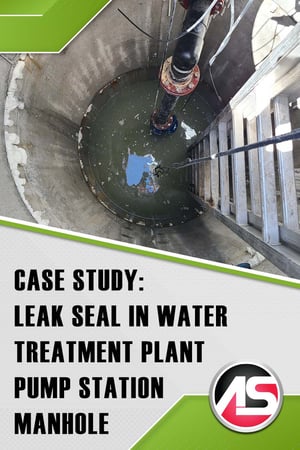

The Central Davis Sewer District (CDSD) is a publicly owned collection system and water treatment plant that serves three local cities in Northern Utah. With a new highway being constructed just outside their facility, a new pump station had to be installed on the premises. After installation of the new pump station, a large leak appeared in the manhole which caused it to fill up with about 10 feet of water. The CDSD contacted PolyFoam Solutions to see what could be done to seal the leaks. The PolyFoam Solutions crew pumped all the water out of the manhole and discovered that two of the manhole’s horizontal joints had large leaks. These leaks were allowing about 10-15 gallons per minute (over 20,000 gallons per day) of water to infiltrate the pump station.

The Central Davis Sewer District (CDSD) is a publicly owned collection system and water treatment plant that serves three local cities in Northern Utah. With a new highway being constructed just outside their facility, a new pump station had to be installed on the premises. After installation of the new pump station, a large leak appeared in the manhole which caused it to fill up with about 10 feet of water. The CDSD contacted PolyFoam Solutions to see what could be done to seal the leaks. The PolyFoam Solutions crew pumped all the water out of the manhole and discovered that two of the manhole’s horizontal joints had large leaks. These leaks were allowing about 10-15 gallons per minute (over 20,000 gallons per day) of water to infiltrate the pump station.

Powerful Polymers

PolyFoam Solutions worked closely with Charlie Lerman, Alchemy-Spetec's Director of Technical Services for the Leak Seal Division. Together, they devised a plan to seal the large leaks using Spetec PUR F400. Spetec PUR F400 is a solvent and phthalate-free, water-reactive, hydrophobic, closed-cell, low viscosity, shrink-free, flexible, one-component polyurethane injection resin designed to stop water leaks. It is also certified to NSF/ANSI/CAN 61 (approved for contact with drinking water).

Painless Procedures

The crew drilled four holes around the lower manhole joint and then installed injection ports. As they pumped the polyurethane grout into the ports, it began to travel around the joint, sealing the leaks. Once the grout had traveled as far as it could from one port, the technician moved on to the next port until the entire joint had been sealed watertight. They used oakum to temporarily seal some of the larger leaks until the grout had time to cure. The upper joint only required 3 port injections due to the speed at which the grout traveled.

Rapid Results

The crew only took about 3 hours to completely seal all of the leaks and return the manhole to service. There was no way the leaks could have been left un-repaired due to the water treatment cost and the potential damage the erosion would have caused. Replacing the manhole would have easily cost three or more times the price of grouting. In this case, the community wins as many tax dollars are being saved.