When an old brick retaining wall in downtown Greenville collapsed and crushed three cars, Wurster Engineering and Construction was called in to stabilize the embankment and install a new wall system. Based out of Greenville, SC, Wurster is a geotechnical engineering and construction firm that specializes in soil and embankment stabilization. The project would require removal of the remaining brick wall, soil nailing the embankment, installing a shotcrete wall, and then tying in a new brick wall to the stabilized embankment.

When an old brick retaining wall in downtown Greenville collapsed and crushed three cars, Wurster Engineering and Construction was called in to stabilize the embankment and install a new wall system. Based out of Greenville, SC, Wurster is a geotechnical engineering and construction firm that specializes in soil and embankment stabilization. The project would require removal of the remaining brick wall, soil nailing the embankment, installing a shotcrete wall, and then tying in a new brick wall to the stabilized embankment.

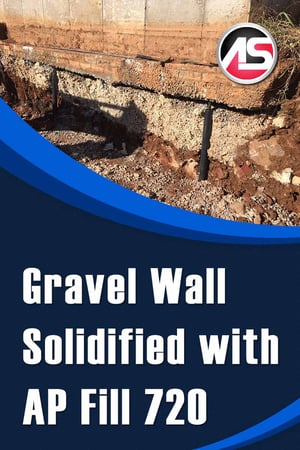

However, one problem remained. There was one area where there was a portion of the brick wall that needed removal, but the temporary concrete retaining wall to protect the property had been poured on a bed of gravel that was being held in place by the remaining brick. The gravel under the temporary wall footing was contained by the remaining brick, which when removed would cause all of the gravel to run out. This section was about 30-35’ long, 2’ high, and 4-5’ deep from the face of the wall to the back.

Powerful Polymer

In order to solve this issue, Wurster Engineering and Construction selected AP Fill 720 to permeate the gravel and hold it in place while the brick was removed. This polyurethane resin was the ideal choice because of its ability to thoroughly permeate the gravel, lock it all together, and then cure to a high compressive strength. With the gravel locked in place, Wurster Engineering and Construction was able to install supplemental support jacks under the temporary retaining wall. After the jacks were in place, they were able to install the soil nails followed by the shotcrete.

Painless Procedure

Approximately 50 gallons of AP Fill 720 were used to build this solidified wall of gravel behind the remaining brick wall. Injection probes were spaced 18” apart to ensure proper permeation and coverage needed to create one solid mass. The crew came in at a steep 20 to 30-degree angle behind the brick and put in about 2 gallons of polyurethane per probe, with 5% catalyst mixed in. The crew then installed more probes at a shallow 60-degree angle in the areas that needed further permeation and coverage. These extra placements of approximately 2 gallons per probe were essential to keeping the gravel in place from side to side and front to back. This entire process took one day to complete with a small crew of three people.

Rapid Result

The day after grouting, the site work demolition subcontractor chiseled off the remaining brick from the solidified AP Fill 720 gravel wall - and the project was determined to be a complete success. The entire job was finished quickly with minimal mobilization costs. We appreciate our friends at Wurster Engineering and Construction for trusting Alchemy-Spetec’s material and consultation for geotechnical projects such as this one.