Soil testing equipment is extremely helpful for planning slab lifting and soil stabilization work. Contractors use ground penetrating radar systems and dynamic cone penetrometers to get a sense of soil conditions before they drill their first hole into a slab or push their first injection pipe into the ground.

Soil testing equipment is extremely helpful for planning slab lifting and soil stabilization work. Contractors use ground penetrating radar systems and dynamic cone penetrometers to get a sense of soil conditions before they drill their first hole into a slab or push their first injection pipe into the ground.

Deep Look™ Ground Penetrating Radar

The Deep Look™ wireless ground penetrating radar collects data from hundreds of thousands of pulse reflections each second to help contractors identify objects below ground. The triple-frequency antenna design provides higher-resolution imaging than conventional GRP systems.

Dynamic Cone Penetrometer

The Pagini DPM30 dynamic cone penetrometer is ideal for testing soil strength and density at various depths. The fact that it is exceptionally small means it can be used on sites that are inaccessible to normal machines. A hydraulic pump raises and drops a weight onto a measuring rod, pushing it into the ground. To measure soil strength, the operator counts the number of blows it takes to drive the steel rod in 10-centimeter increments. Good soil requires 10+ blows to drive the rod 10 centimeters. Anything less is typically indicative of weak soil conditions.

Want more info on geotech equipment and repair materials?

Topics:

Equipment & Accessories,

Lift Slabs,

Stabilize Soil,

Deep Lift,

Deep Lock

Alchemy-Spetec HQ in Tucker, GA

THIS EVENT HAS BEEN CANCELLED

$745 Registration Fee

$745 Registration Fee

$665 for each additional participant from

the same company.

Get ready for a thorough education in Slab Lifting, Soil Stabilization, the Alchemy-Spetec Deep Lift® process, equipment, and applications. You’ll get hands-on training from a technical staff with decades of on-the-job experience.

Tuesday, October 4th

- Geotech Product Line Overview

- Geotech Applications & Case Studies

- MixMaster Pro Slab Lifting Gun

- Slab Lift Rig Demonstration

Wednesday, October 5th

- Pump Demos & Training

- PolyShark® / Soil Stabilization

- Deep Lift®

- Ground Penetrating Radar

Thursday, March 31st

- PolyBadger® Mobile Slab Lifting System

- Estimating Material for Jobs

THIS EVENT HAS BEEN CANCELLED

Topics:

Equipment & Accessories,

All Posts,

Lift Slabs,

Stabilize Soil,

Business Tips,

Deep Lift,

Fill Voids

Alchemy-Spetec HQ in Tucker, GA

THIS EVENT HAS BEEN CANCELLED

$745 Registration Fee

$745 Registration Fee

$665 for each additional participant from

the same company.

Get ready for a thorough education in Slab Lifting, Soil Stabilization, the Alchemy-Spetec Deep Lift® process, equipment, and applications. You’ll get hands-on training from a technical staff with decades of on-the-job experience.

Tuesday, October 4th

- Geotech Product Line Overview

- Geotech Applications & Case Studies

- MixMaster Pro Slab Lifting Gun

- Slab Lift Rig Demonstration

Wednesday, October 5th

- Pump Demos & Training

- PolyShark® / Soil Stabilization

- Deep Lift®

- Ground Penetrating Radar

Thursday, March 31st

- PolyBadger® Mobile Slab Lifting System

- Estimating Material for Jobs

THIS EVENT HAS BEEN CANCELLED

Topics:

Equipment & Accessories,

All Posts,

Lift Slabs,

Stabilize Soil,

Business Tips,

Deep Lift,

Fill Voids

Alchemy-Spetec HQ in Tucker, GA

THIS EVENT HAS BEEN CANCELLED

$745 Registration Fee

$745 Registration Fee

$665 for each additional participant from

the same company.

Get ready for a thorough education in Slab Lifting, Soil Stabilization, the Alchemy-Spetec Deep Lift® process, equipment, and applications. You’ll get hands-on training from a technical staff with decades of on-the-job experience.

Tuesday, October 4th

- Geotech Product Line Overview

- Geotech Applications & Case Studies

- MixMaster Pro Slab Lifting Gun

- Slab Lift Rig Demonstration

Wednesday, October 5th

- Pump Demos & Training

- PolyShark® / Soil Stabilization

- Deep Lift®

- Ground Penetrating Radar

Thursday, March 31st

- PolyBadger® Mobile Slab Lifting System

- Estimating Material for Jobs

THIS EVENT HAS BEEN CANCELLED

Topics:

Equipment & Accessories,

All Posts,

Lift Slabs,

Stabilize Soil,

Business Tips,

Deep Lift,

Fill Voids

Alchemy-Spetec HQ in Tucker, GA

THIS EVENT HAS BEEN CANCELLED

$745 Registration Fee

$745 Registration Fee

$665 for each additional participant from

the same company.

Get ready for a thorough education in Slab Lifting, Soil Stabilization, the Alchemy-Spetec Deep Lift® process, equipment, and applications. You’ll get hands-on training from a technical staff with decades of on-the-job experience.

Tuesday, October 4th

- Geotech Product Line Overview

- Geotech Applications & Case Studies

- MixMaster Pro Slab Lifting Gun

- Slab Lift Rig Demonstration

Wednesday, October 5th

- Pump Demos & Training

- PolyShark® / Soil Stabilization

- Deep Lift®

- Ground Penetrating Radar

Thursday, March 31st

- PolyBadger® Mobile Slab Lifting System

- Estimating Material for Jobs

THIS EVENT HAS BEEN CANCELLED

Topics:

Equipment & Accessories,

All Posts,

Lift Slabs,

Stabilize Soil,

Business Tips,

Deep Lift,

Fill Voids

The residents of a house in Columbia, Missouri noticed the floor in their finished basement was settling. The slab was beginning to sink along the base of a load-bearing wall. It turned out that there was no structural support beneath that area of the floor. They reached out to Absolute Foundation Repair, a local geotechnical contractor. Alchemy-Spetec Geotech Services Technician Jacob Bryant was invited by the contractor to consult on the job as well.

The residents of a house in Columbia, Missouri noticed the floor in their finished basement was settling. The slab was beginning to sink along the base of a load-bearing wall. It turned out that there was no structural support beneath that area of the floor. They reached out to Absolute Foundation Repair, a local geotechnical contractor. Alchemy-Spetec Geotech Services Technician Jacob Bryant was invited by the contractor to consult on the job as well.

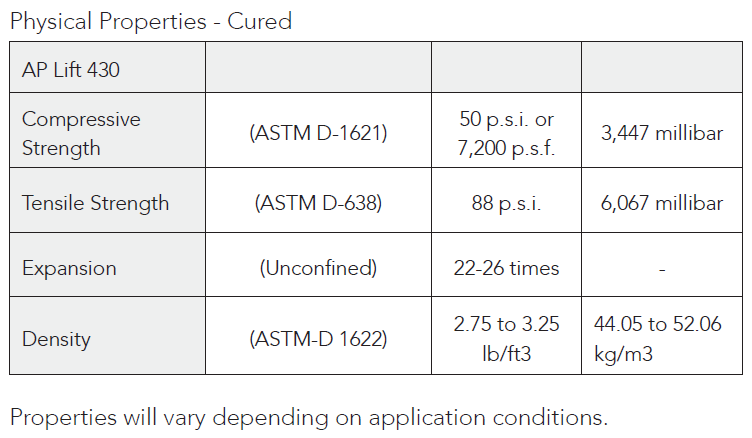

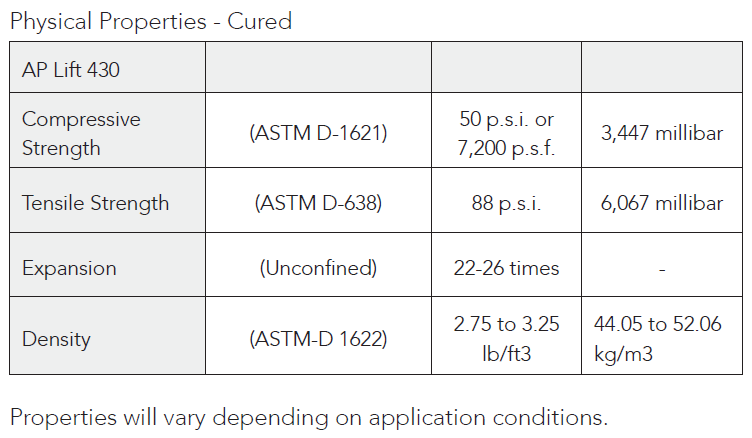

Powerful Polymers

AP Lift 430 is a two-component, high-strength, high-density, hydro-insensitive structural polyurethane foam. This very reliable and consistent material was selected because it is ideal for strengthening and compacting soil. This high-strength closed cell polyurethane bonds with soil and concrete. After installation, the site is often traffic ready in as soon as 15 minutes. AP Lift 430 is also certified to NSF/ANSI/CAN 61 (approved for contact with drinking water).

Painless Procedures

The Alchemy-Spetec technical consultant worked closely with the geotech contractor to develop the injection plan. The crew removed the carpet and then drilled holes every three feet along the length of the affected area. Next, they drove injection tubing through each drill hole, four feet deep into the soil beneath the slab. A technician then injected about 20-40 lbs of AP Lift 430 per tube. The crew monitored for lift during this process. The slab was raised about 1/8 - 1/4 of an inch to ensure that the soil was fully compacted. Next, they injected additional material just beneath the slab (a.k.a. shallow injections) to fill any remaining voids. Finally, they removed the tubes and cleaned up the site.

Rapid Results

After only a few hours, the job was completed, and the site was completely cleaned up. The customer was able to conduct her previously scheduled dance class on that same floor later that day.

Want more information on geotech products?

Topics:

All Posts,

Stabilize Soil,

Deep Lift

Settling Garage Floor Slab – Causes

Settling Garage Floor Slab – Causes

As with most slab settling issues, voids and poor soil compaction are at the root of the problem. This is certainly the case with sunken garage slabs. They are typically constructed by backfilling the area after the foundation is poured (or blocked) and pouring the concrete on top. Achieving proper and adequate compaction is often difficult and just not achieved in many cases. This, combined with time and freeze/thaw cycles creates voids under the garage slab. Concrete itself is heavy and can settle, but when we park vehicles on top of a garage slab that has voids under it? It is obviously a recipe for disaster!

Settling Garage Floor Slab – Solution

Alchemy-Spetec can refer you to a contractor for a thorough site evaluation. A qualified contractor takes the time to properly inspect the issue, which generally entails probing the slab to determine if there is indeed a void and/or unstable soil (and to what extent). Gathering this type of information is key to designing a proper repair plan and calculating the amount of polyurethane lifting material needed.

Depending on the conditions found during site evaluation, there are a couple of different techniques the contactor may use (and oftentimes both). If the soil under the garage slab is soft and unstable to a certain depth, they may opt for the Deep Lift® method. The expanding structural foam creates a squeeze effect in the loose soil, essentially forming added support footings under the slab. The other injection method, Slab Lifting, entails going through ⅜-inch holes drilled directly through the slab. The same structural foam described above is used. The expanding foam travels the path of least resistance, therefore, filling all void areas as well as compacting any loose soil. Once the soil is compact, the expansion of the foam creates the power to lift the slab. Our high-density polyurethane cures to 90% in fifteen minutes – which translates to the slab being traffic-ready by the time we are packing up our equipment.

Want more info on the Deep Lift® and Slab Lift methods?

Topics:

All Posts,

Lift Slabs,

Deep Lift

We often assume that our homes, roadways, and buildings are resting on solid ground - until that support starts to give way. The same natural element that carved out the Grand Canyon causes unstable soil, voids, and even sinkholes. Water is relentless and your property is at risk if soil damage is left unchecked. Poor compaction, water erosion, broken pipes, and organic material in the soil can all lead to the settling of a foundation or a roadway. Ignoring soil erosion underneath your property can lead to disaster.

We often assume that our homes, roadways, and buildings are resting on solid ground - until that support starts to give way. The same natural element that carved out the Grand Canyon causes unstable soil, voids, and even sinkholes. Water is relentless and your property is at risk if soil damage is left unchecked. Poor compaction, water erosion, broken pipes, and organic material in the soil can all lead to the settling of a foundation or a roadway. Ignoring soil erosion underneath your property can lead to disaster.

Outdated methods of addressing deep soil issues require heavy equipment, extended downtime, and collateral property damage. Alchemy-Spetec's factory-trained contractors offer a unique combination of high-quality structural lifting foams along with the equipment and training needed to address deep soil issues. Our polyurethane resin technology has been proven in use around the world and is certified to be environmentally friendly.

Solving Deep Soil Issues with the Deep LiftⓇ Process

Contractors trained in Alchemy-Spetec's Deep LiftⓇ process achieve deep soil densification and lift on large projects with the smallest footprint and the least amount of heavy equipment required. This process brings the structure back to level with minimal downtime for the property owner.

The Deep LiftⓇ Property Preservation Plan

With our support, we can help you save your property, save your money, and save your peace of mind.

- Start a conversation with one of our experts.

- We will connect you to a factory-trained contractor.

- The contractor will create an action custom action plan for your property.

Topics:

All Posts,

Deep Lift

The Geotechnical Applications for Polyurethane presentation explains and demonstrates how concrete leveling and soil stabilization resins can be used to stabilize soil and repair structures. The presentation covers the following topics:

The Geotechnical Applications for Polyurethane presentation explains and demonstrates how concrete leveling and soil stabilization resins can be used to stabilize soil and repair structures. The presentation covers the following topics:

- Single Component Polyurethane Grout Applications

- Two-Component Polyurethane Grout Applications

- Acrylic Grout Applications

This one-hour CE/PDH accredited presentation is ideal for engineers who are interested in learning about next-generation geotech repair methods for pavement lifting and stabilization, excavation support, erosion control, infrastructure infiltration control, etc.

Click here and submit your info for a follow-up call on scheduling an accredited presentation.

Want more information on geotech products and equipment?

Topics:

All Posts,

Lift Slabs,

Stabilize Soil,

Deep Lift,

Fill Voids,

Engineer Resources

On March 29th - 31st, Contractors from around the world traveled to Alchemy-Spetec HQ in Tucker, GA for a thorough education in Slab Lifting, Soil Stabilization, the Deep Lift® process, equipment, and applications. They received hands-on training from a technical staff with decades of on-the-job experience.

On March 29th - 31st, Contractors from around the world traveled to Alchemy-Spetec HQ in Tucker, GA for a thorough education in Slab Lifting, Soil Stabilization, the Deep Lift® process, equipment, and applications. They received hands-on training from a technical staff with decades of on-the-job experience.

This three-day geotech bootcamp featured presentations and demos on the following subjects:

- Geotech Product Line Overview

- Geotech Applications & Case Studies

- PolyBadger® Demo & Training

- Estimating & Quoting Jobs

- PMC Pump Demo & Training

- Leak Seal Issues on Geotech Jobs

- Ground Penetrating Radar Demo & Training

- Slab Lift Rig Demo & Training

- Competing Geotech Techniques

- PolyShark® / Soil Stabilization Demo & Training (On-Site)

- Deep Lift® Demo & Training (On-Site)

All of us here at Alchemy-Spetec would like to thank everyone who participated! and extend an invitation to those who missed this event to sign up below for notifications on future training programs.

Topics:

All Posts,

Lift Slabs,

Stabilize Soil,

Business Tips,

Deep Lift,

Fill Voids

Soil testing equipment is extremely helpful for planning slab lifting and soil stabilization work. Contractors use ground penetrating radar systems and dynamic cone penetrometers to get a sense of soil conditions before they drill their first hole into a slab or push their first injection pipe into the ground.

Soil testing equipment is extremely helpful for planning slab lifting and soil stabilization work. Contractors use ground penetrating radar systems and dynamic cone penetrometers to get a sense of soil conditions before they drill their first hole into a slab or push their first injection pipe into the ground.

The residents of a house in Columbia, Missouri noticed the floor in their finished basement was settling. The slab was beginning to sink along the base of a load-bearing wall. It turned out that there was no structural support beneath that area of the floor. They reached out to

The residents of a house in Columbia, Missouri noticed the floor in their finished basement was settling. The slab was beginning to sink along the base of a load-bearing wall. It turned out that there was no structural support beneath that area of the floor. They reached out to

Settling Garage Floor Slab – Causes

Settling Garage Floor Slab – Causes

We often assume that our homes, roadways, and buildings are resting on solid ground - until that support starts to give way. The same natural element that carved out the Grand Canyon causes unstable soil, voids, and even sinkholes. Water is relentless and your property is at risk if soil damage is left unchecked. Poor compaction, water erosion, broken pipes, and organic material in the soil can all lead to the settling of a foundation or a roadway. Ignoring soil erosion underneath your property can lead to disaster.

We often assume that our homes, roadways, and buildings are resting on solid ground - until that support starts to give way. The same natural element that carved out the Grand Canyon causes unstable soil, voids, and even sinkholes. Water is relentless and your property is at risk if soil damage is left unchecked. Poor compaction, water erosion, broken pipes, and organic material in the soil can all lead to the settling of a foundation or a roadway. Ignoring soil erosion underneath your property can lead to disaster.

The Geotechnical Applications for Polyurethane presentation explains and demonstrates how

The Geotechnical Applications for Polyurethane presentation explains and demonstrates how

On March 29th - 31st, Contractors from around the world traveled to Alchemy-Spetec HQ in Tucker, GA for a thorough education in Slab Lifting, Soil Stabilization, the Deep Lift® process, equipment, and applications. They received hands-on training from a technical staff with decades of on-the-job experience.

On March 29th - 31st, Contractors from around the world traveled to Alchemy-Spetec HQ in Tucker, GA for a thorough education in Slab Lifting, Soil Stabilization, the Deep Lift® process, equipment, and applications. They received hands-on training from a technical staff with decades of on-the-job experience.