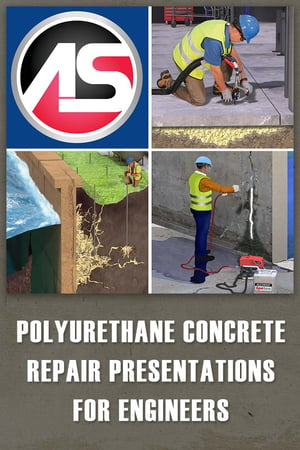

Alchemy-Spetec offers one-hour CE/PDH accredited presentations on polyurethane concrete repair. Presentation topics offered include Leak Seal, Geotech, and Seawall Repair. Here is a detailed overview...

Alchemy-Spetec offers one-hour CE/PDH accredited presentations on polyurethane concrete repair. Presentation topics offered include Leak Seal, Geotech, and Seawall Repair. Here is a detailed overview...

Leak Seal Presentation

The Specialty Waterproofing with Chemical Grouts presentation covers sealing leaks in structures with the use of polyurethane chemical grout injection materials and techniques.

- Chemical Grouting Primer

- History

- Safety

- Characteristics

- Utilization & Applications

- Identifying Applications

- Selecting a Chemical Grout

- Epoxy & Hydraulic Cement

- Installation Techniques

- Crack and Joint Injection

- Curtain Grouting

- Oakum Soakum

- Equipment Overview

Alchemy-Spetec's one-hour CE/PDH accredited Leak Seal presentation is perfect for engineers looking for information on innovative and proven leak seal repair methods for sealing leaks in structures, inflow/infiltration mitigation, and more.

Geotech Presentation

The Geotechnical Applications for Polyurethane presentation explains three types of concrete leveling and soil stabilization materials and applications.

- Single Component Polyurethane Grout Applications

- Two-Component Polyurethane Grout Applications

- Acrylic Grout Applications

Alchemy-Spetec's one-hour CE/PDH accredited Geotech presentation is perfect for engineers looking for information on innovative and proven geotechnical repair methods for lifting concrete, soil stabilization, excavation support, controlling erosion, and more.

Seawall Repair Network Presentation

The Seawall Stabilization and Preservation through Permeation Presentation explains and demonstrates how Seawall Repair Network contractors use polyurethane injection resin and surface-applied preservation solutions to stabilize and preserve seawalls and bulkheads. (Seawall Repair Network is a division of Alchemy-Spetec.)

- The Causes of Seawall Failure

- Stabilizing a Seawall

- Preserving a Seawall

- Stabilization & Preservation Through Permeation

Alchemy-Spetec's one-hour CE/PDH accredited Seawall Repair Network presentation is ideal for engineers who are interested in designing superior seawall/bulkhead rehabilitation and preservation solutions. This type of environmentally friendly permanent soil stabilization and seawall preservation can be applied to all types of waterfront infrastructure.

The new and improved PolyShark 2.0 is here!

The new and improved PolyShark 2.0 is here!

It's not an exaggeration to say that that the PolyShark

It's not an exaggeration to say that that the PolyShark

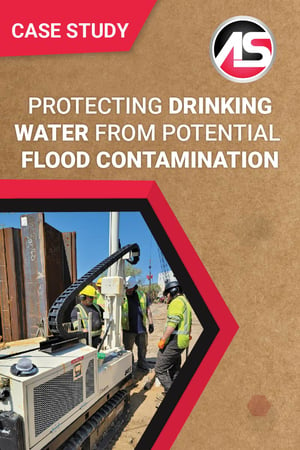

Planners at Washington D.C.’s water utility,

Planners at Washington D.C.’s water utility,

Editor's Note: An earlier version of this article was published under the title Develop Your Competitive Edge.

Editor's Note: An earlier version of this article was published under the title Develop Your Competitive Edge.

AP Pump Saver 195

AP Pump Saver 195

This article features intros and links to our top 5 most popular seawall repair blogs:

This article features intros and links to our top 5 most popular seawall repair blogs:

Whether it’s your first time or you’re a seasoned veteran, this guide can serve as a simple checklist to keep your equipment and 16-20 foot trailer safe as you travel to your next project.

Whether it’s your first time or you’re a seasoned veteran, this guide can serve as a simple checklist to keep your equipment and 16-20 foot trailer safe as you travel to your next project.

This post is part of the

This post is part of the